Say goodbye to unscheduled production stoppages Put an end to torn, prematurely worn belts

Protect your equipment

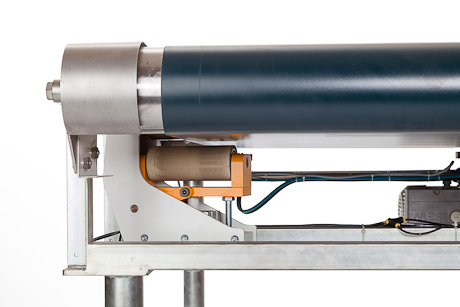

Everyone who uses / designs belt conveyor transport systems wants them to work as well as possible. This goal is often not achieved! One of the main reasons for this is improper belt guidance, which causes stoppages, premature wear and even deterioration of the belt or production losses. BT series guiding systems can resolve this problem. The BT Belt Trackers can guide all types of belts (cotton, polyester, rubber, PTFE-coated fibreglass, polyester filter belts, mesh belts, etc.) and can be used in all applications (transporting biscuits, sheet metal, filtering, etc.).

Advantages of BT systems

- Automatic belt tracking correction

- Reduction of unwanted stoppages of the machine resulting in increased productivity

- Maintenance is greatly reduced

- Small footprint

- Operates in harsh environments and high temperatures

- Pneumatic or electrical detection of belt misalignment

- Works at high speeds

- Low energy consumption: the system starts up when the belt travels off track

How it works

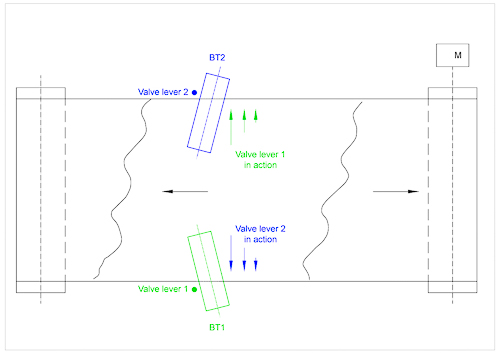

The BT guides are placed on the return side of the belt, angled at ± 10° in the direction of travel of the belt. When the side of the belt comes into contact with the pneumatic or electrical limit stop of the BT 1, the BT 2 activates; it pinches the side of the belt, drawing it towards the BT 2. When the belt reaches the correct position, the BT 2 deactivates. The tracking correction cycle will repeat when the edge of the belt comes into contact with the BT 1 or BT 2 limit stop.BT Types

BT500